Alfa Turbo Teknik prepares remedial services for the diesel components stated at many various brands. Company’s repair activities at workshop is based on availability of :

- Experienced Technicians

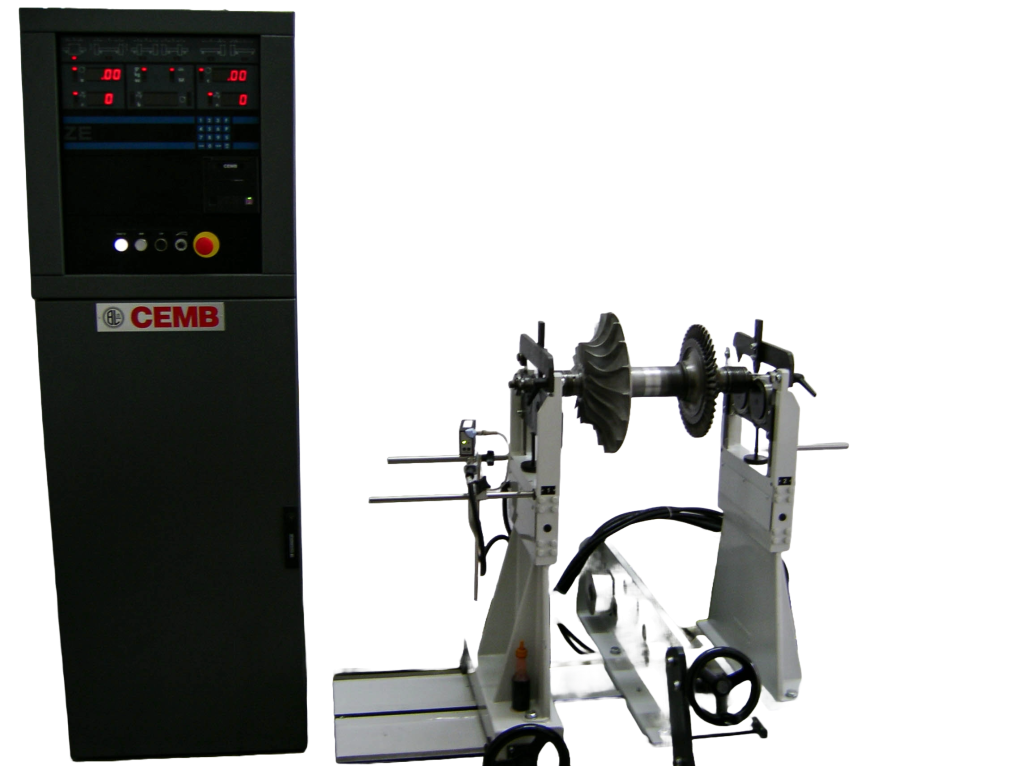

- Modern Equipment & Tools

- Efficient Repair Procedures.

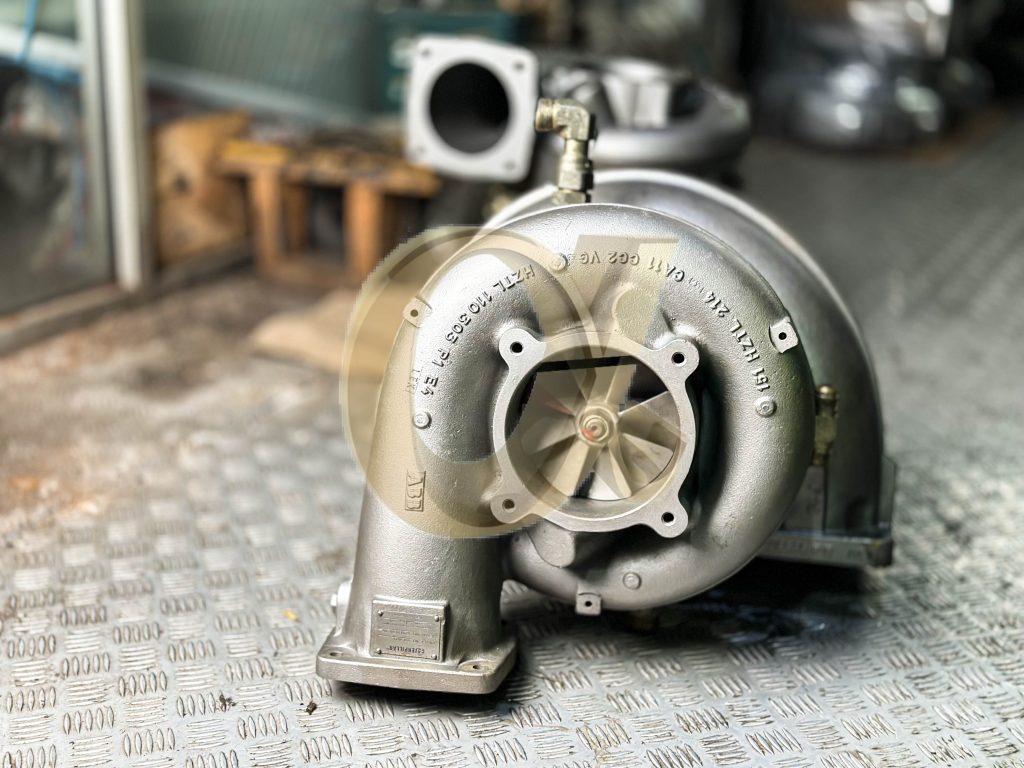

Professional turbocharger service typically involves a series of steps aimed at diagnosing, repairing, or replacing turbocharger components to ensure optimal performance of the Engine. Here’s an outline of what you might expect from a professional turbocharger service experience:

- Initial Assessment: The process usually begins with a thorough examination of the turbocharger system. This includes visual inspection, listening for unusual noises, and possibly conducting diagnostic tests using specialized equipment to identify any issues.

- Diagnosis: Based on the assessment, the technician will diagnose the specific problem(s) affecting the turbocharger. This could range from issues with the turbo bearings, wastegate, compressor, or turbine blades to problems with the oil supply or exhaust system.

- Repair or Replacement Plan: Once the problem is identified, the technician will develop a repair or replacement plan. In some cases, minor issues can be resolved through repairs such as fixing leaks or replacing damaged components. However, if the turbocharger is severely damaged or worn out, a replacement may be necessary.

- Parts Sourcing: If replacement parts are needed, the service center will source genuine or high-quality aftermarket components suitable for your vehicle’s make and model.

- Turbocharger Removal: If a replacement is necessary, the old turbocharger will be removed from the vehicle. This involves disconnecting various hoses, pipes, and electrical connections, as well as unbolting the turbocharger from the engine.

- Balancing Calibration: the technician will conduct tests Balancing to ensure the turbocharger is functioning correctly. This may involve running the Rotor Assy and monitoring performance parameters such as loosen vibration for rotating Rotor that still may have big vibration following factory data literatures.

- Installation of New Turbocharger: The new or refurbished turbocharger will be installed onto the engine following manufacturer-recommended procedures. This includes properly torquing bolts, connecting hoses and pipes, and ensuring all components are correctly aligned.

- Quality Check and Final Inspection: Once testing is complete, a final inspection will be carried out to ensure everything is in order. This includes checking for leaks, abnormal noises, and any other signs of potential issues.

- Customer Consultation: Finally, the technician will consult with you, the customer, to explain the work that was done, any recommendations for ongoing maintenance, and answer any questions you may have.

- Follow-Up: Offer follow-up check-ins to ensure that the turbocharger continues to perform optimally and address any concerns that may arise post-service.

A professional turbocharger service is essential for maintaining the performance and longevity of your engine, particularly in turbocharged engines where the turbocharger plays a crucial role in power delivery.